2.2 Properties of Concrete

2.2.1 Compressive Strength

1.Cube Compressive Strength

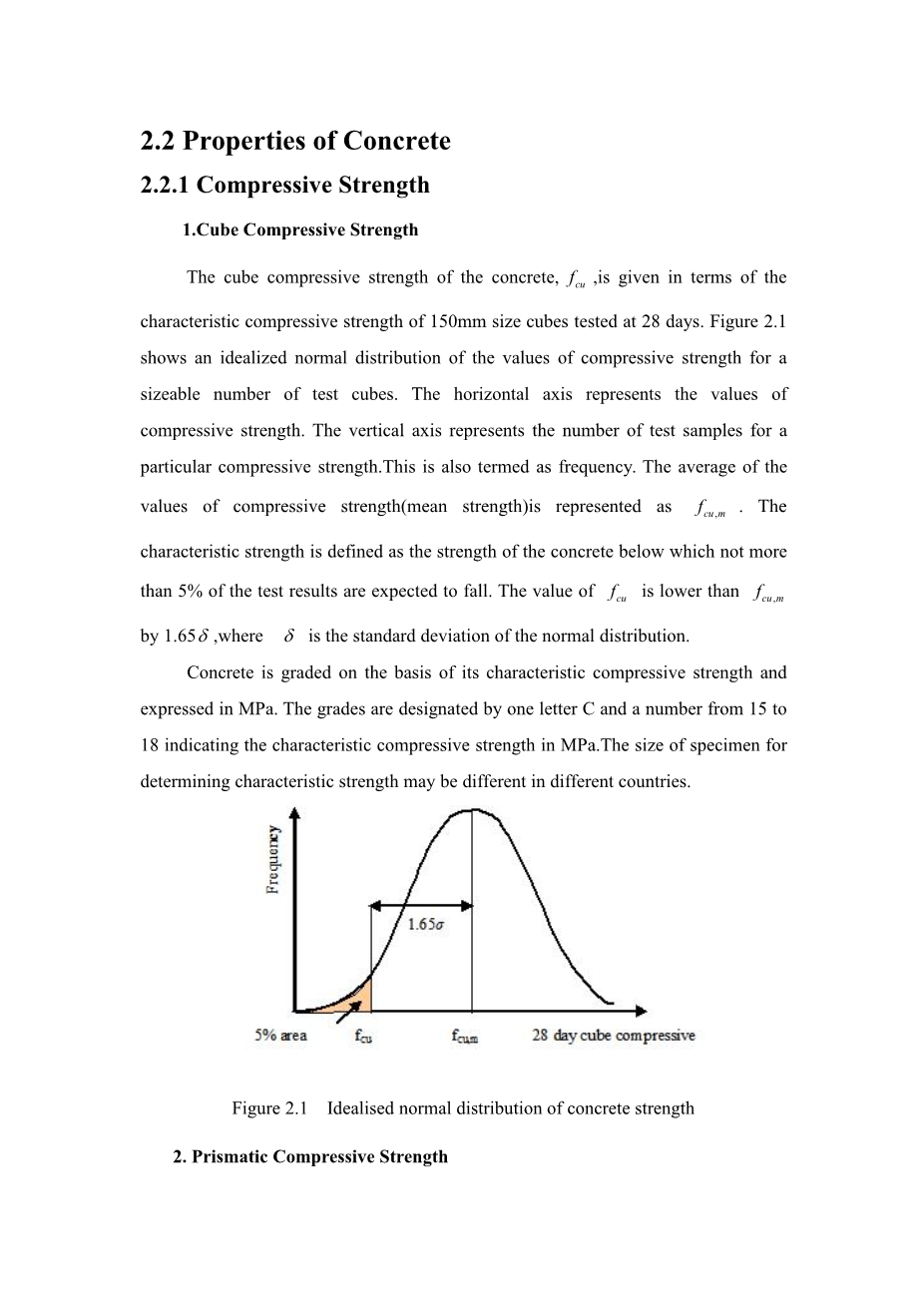

The cube compressive strength of the concrete,,is given in terms of the characteristic compressive strength of 150mm size cubes tested at 28 days. Figure 2.1 shows an idealized normal distribution of the values of compressive strength for a sizeable number of test cubes. The horizontal axis represents the values of compressive strength. The vertical axis represents the number of test samples for a particular compressive strength.This is also termed as frequency. The average of the values of compressive strength(mean strength)is represented as . The characteristic strength is defined as the strength of the concrete below which not more than 5% of the test results are expected to fall. The value of is lower than by 1.65,where is the standard deviation of the normal distribution.

Concrete is graded on the basis of its characteristic compressive strength and expressed in MPa. The grades are designated by one letter C and a number from 15 to 18 indicating the characteristic compressive strength in MPa.The size of specimen for determining characteristic strength may be different in different countries.

Figure 2.1 Idealised normal distribution of concrete strength

2. Prismatic Compressive Strength

The prismatic compressive strength () of concrete is close to the axial compressive strength of concrete in column. Prismatic specimens with a height-to-width aspect ratio of 3 to 4 are adopted.

2.2.2 Tensile Strength

The tensile strength of concrete can be expressed as follows:

1 .Axial Tensile Strength

It is measured by testing prismatic specimens under direct tension .There are con-siderable difficulties in determining the true tensile strength of concrete . Minor misa-lignment and stress concentration in the graping devices are apt to mar the result.

The following expression gives an extimation of axial tensile strength ()of con-crete from its characteristic cube compressive strength.

(2.2.2)

2.Splitting Tensile Strength

The result of split-cube test is a measure of the tensile strength of concrete.A 150mm concrete cube, the same as the one used for cube compressive test,is inserted in a compression testing machine. Pads are inserted between the compression platens of the machine and the cube to equalize and distribute the pressure. It can be shown that in an elastic cube so loaded, a nearly uniform tensile stress of magnitude exists at the right angle to the plane of loading application. Correspondingly, such cube, when tested, splits into two halves along that plane, at a stressthat can be computed from the equation ,where P is the applied compressive load at failure,and a is the length of cube.

Figure 2.2 Tensile test

2.2.3The Modulus of Elasticity

The modulus of elasticity is determined from a low cycle loading test of prismatic specimen. The loading is limited to a maximum value of . The loading-unloading cycle is repeated 5 to 10 times.See Figure 2.3.

Figure 2.3 Stress-strain curve of concrete obtained from a low cycle loading test

The modulus of elasticity obtained from low cycle loading test is given by the following equation

(2.2.2)

where,

modulus of elasticity in MPa

characteristic compressive strength of cubes in MPa

2.2.4 Shrinkage of Concrete

Any workable concrete mix contains more water than is needed for hydration. If the concrete is exposed to air , the large part of this free water evaporates in time , the rate and completeness of drying depending on ambient temperature and humidity conditions. As the concrete dries, it shrinks in volume, probably due to the capillary tension that develops in the water remaining in the concrete. Conversely, if dry concrete is immersed in water, it expands, regaining much of the volume loss from prior shrinkage. Shrinkage, which continues at a decreasing rate for several months, depending on the configuration of the member, is a detrimental property of concrete in several respects. When not adequately controlled, it will cause unsightly and deleterious cracks, as in slabs, walls, etc. In structures that are statically indeterminate(and most concrete structures are), it can cause large and harmful stresses. In prestressed concrete it leads to partial loss of initial prestress. For these reasons, it is essential that shrinkage be minimized and controlled.

1. Effect of Cement and Water Contents on Shrinkage

Water content is probably the largest single factor influencing the shrinkage of paste and concrete. Typical shrinkage values for concrete specimens with a 5 to 1 aggregate-cement ratio are 0.04, 0.06, 0.075 and 0.085 percent for water-cement ratios of 0.4,0.5,0.6 and 0.7, respectively. One of the reason is that the density and composition of calcium silicate formed at different water-cement ratios may be slightly different. In general, a higher cement content increases the shrinkage of concrete; the relative shrinkages of neat paste, mortar and concrete may be of the order of about 5,2 and 1.

Fineness of cement seems to be a factor in shrinkage and particles coarse than No.200 sieve, which react with water very slowly, have a restraining effect similar to that of aggregate. Thus, high-early-strength cement, which is finely ground, shrinks about 10 percent more than normal cement. Low-heat and portland-pozzolan cements shrink a further 20 and 35 percent, respectively. This is believed to be caused by larger quantitie

剩余内容已隐藏,支付完成后下载完整资料

英语原文共 21 页,剩余内容已隐藏,支付完成后下载完整资料

资料编号:[138043],资料为PDF文档或Word文档,PDF文档可免费转换为Word

您可能感兴趣的文章

- 饮用水微生物群:一个全面的时空研究,以监测巴黎供水系统的水质外文翻译资料

- 步进电机控制和摩擦模型对复杂机械系统精确定位的影响外文翻译资料

- 具有温湿度控制的开式阴极PEM燃料电池性能的提升外文翻译资料

- 警报定时系统对驾驶员行为的影响:调查驾驶员信任的差异以及根据警报定时对警报的响应外文翻译资料

- 门禁系统的零知识认证解决方案外文翻译资料

- 车辆废气及室外环境中悬浮微粒中有机磷的含量—-个案研究外文翻译资料

- ZigBee协议对城市风力涡轮机的无线监控: 支持应用软件和传感器模块外文翻译资料

- ZigBee系统在医疗保健中提供位置信息和传感器数据传输的方案外文翻译资料

- 基于PLC的模糊控制器在污水处理系统中的应用外文翻译资料

- 光伏并联最大功率点跟踪系统独立应用程序外文翻译资料