英语原文共 2 页,剩余内容已隐藏,支付完成后下载完整资料

Abstract: Glulam beams were prepared using pine boards glued together with a melamine-urea–formaldehyde (MUF) adhesive by means of an experimental fast-setting process called “honeymoon”. In this process, MUF is spread on the face of the first part, then an acid is spread on the face of the second part and the two are assembled. Mechanical properties of the beams remain very good even after severe water exposure in a delamination test. Moreover, the short pressing time of this honeymoon process (the adhesive is perfectly hardened after 3 h) makes it perfectly suitable for industrial applications.

摘要:胶合梁是松木板用三聚氰胺-尿素-甲醛胶黏剂(MUF)通过被称为“蜜月”的快速粘结过程制备的。在这个过程中,MUF胶散布在第一部分的表面,然后酸分布在第二部分的表面,然后两部分粘结起来。梁即使在通过一个高压水的脱层测试后其机械性能仍然非常优秀。此外,蜜月进程的短暂性(胶粘剂是完全硬化后3小时)使其完全适合于工业应用。

1 Introduction

Glulam laminated timber beams are widely used in the building trade. The main interest lies in the possibility to produce beams of great length, width and resistance with smaller boards of wood glued together, obtained from small trees from secondary or tertiary forests and plantations. Industrial adhesives such as melamine-urea–formaldehyde or phenol-resorcinol–formaldehyde are used to glue the pieces of wood together. It is of interest to see whether the honeymoon fast-setting process could be used to make glulam beams strong enough to meet the standard requirements.

1引言

胶合层积梁被广泛应用于建筑行业。主要特点在于有可能用从二级或三级森林和种植园中的小型树木制成的木板胶合产生更长、更宽、更抗压的板材。工业粘合剂,如三聚氰胺-尿素-甲醛或苯酚-间苯二酚-甲醛常用于胶合木材。这要看蜜月快凝过程用来制造胶合木梁是否能够符合标准要求。

2 Materials and methods

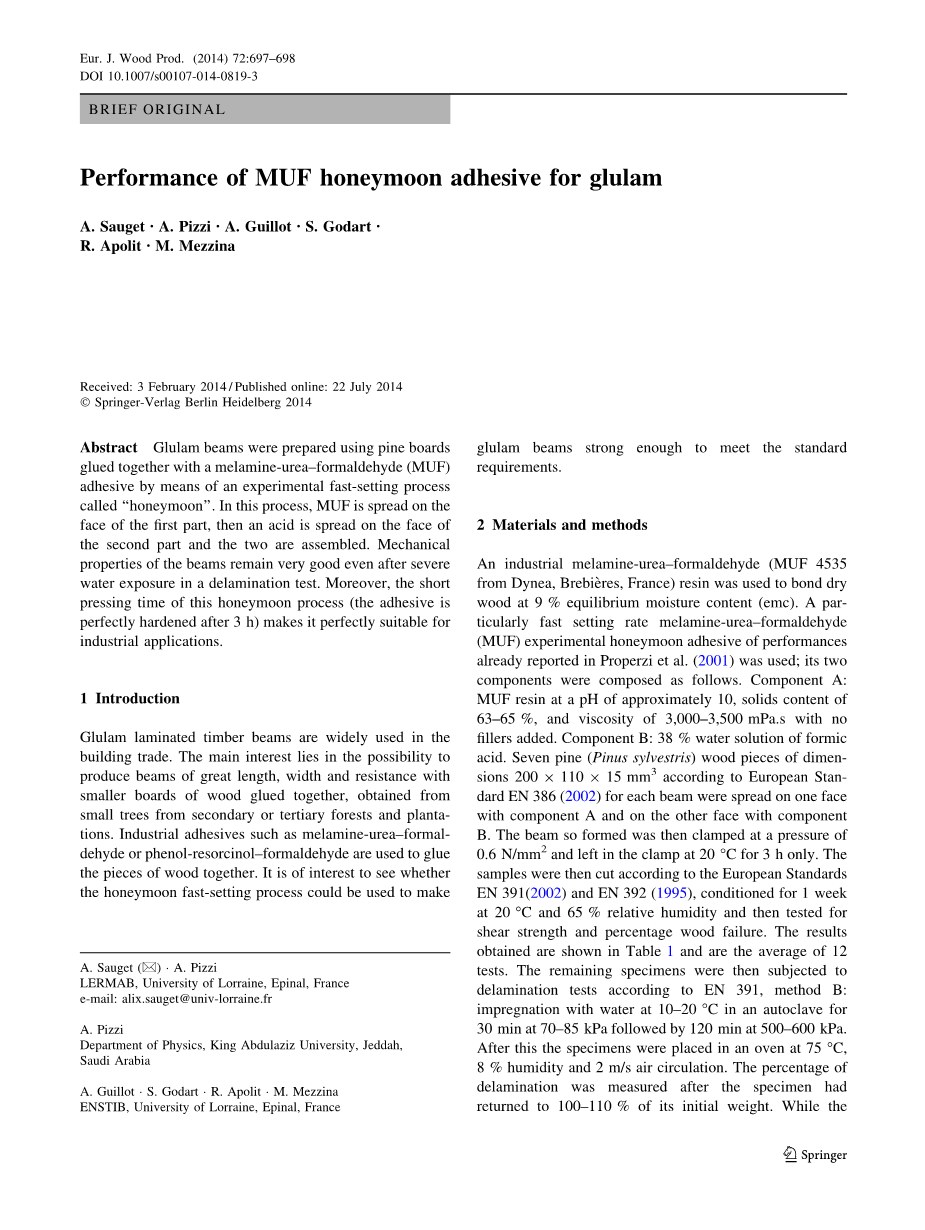

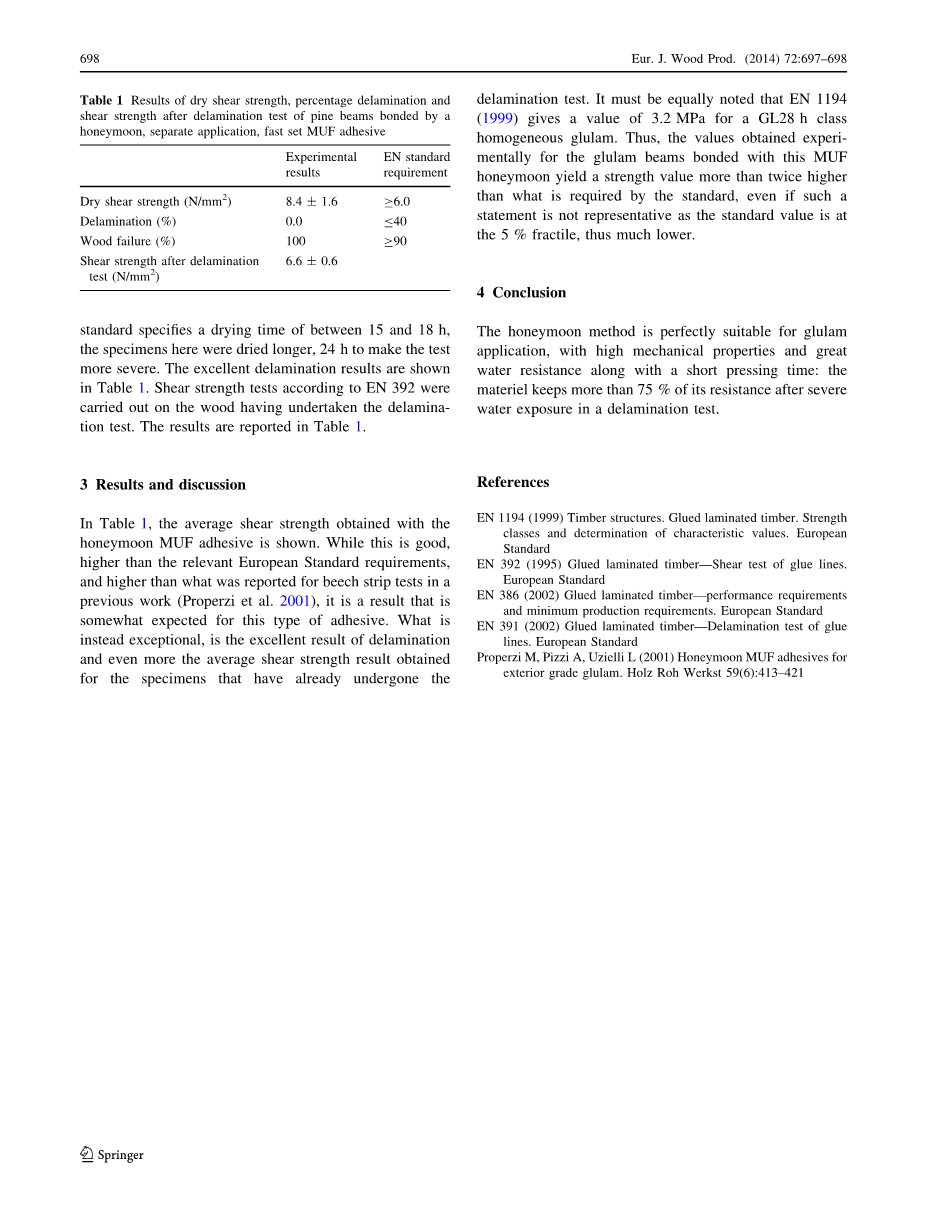

An industrial melamine-urea–formaldehyde (MUF 4535 from Dynea, Brebie `res, France) resin was used to bond dry wood at 9 % equilibrium moisture content (emc). A particularly fast setting rate melamine-urea–formaldehyde (MUF) experimental honeymoon adhesive of performances already reported in Properzi et al. (2001) was used; its two components were composed as follows. Component A: MUF resin at a pH of approximately 10, solids content of 63–65 %, and viscosity of 3,000–3,500 mPa.s with no fillers added. Component B: 38 % water solution of formic acid. Seven pine (Pinus sylvestris) wood pieces of dimensions 200times;110times;15 mmsup3; according to European Standard EN 386 (2002) for each beam were spread on one face with component A and on the other face with component B. The beam so formed was then clamped at a pressure of 0.6 N/mm2 and left in the clamp at 20 ℃ for 3h only. The samples were then cut according to the European Standards EN 391(2002) and EN 392 (1995), conditioned for 1 week at 20 ℃ and 65 % relative humidity and then tested for shear strength and percentage wood failure. The results obtained are shown in Table 1 and are the average of 12 tests. The remaining specimens were then subjected to delamination tests according to EN 391, method B: impregnation with water at 10–20 ℃ in an autoclave for 30 min at 70–85 kPa followed by 120 min at 500–600 kPa. After this the specimens were placed in an oven at 75 ℃, 8 % humidity and 2 m/s air circulation. The percentage of delamination was measured after the specimen had returned to 100–110 % of its initial weight. While the Table 1 Results of dry shear strength, percentage delamination and shear strength after delamination test of pine beams bonded by a honeymoon, separate application, fast set MUF adhesive standard specifies a drying time of between 15 and 18 h, the specimens here were dried longer, 24 h to make the test more severe. The excellent delamination results are shown in Table 1. Shear strength tests according to EN 392 were carried out on the wood having undertaken the delamination test. The results are reported in Table 1.

2材料与方法

一种工业三聚氰胺尿素甲醛(MUF 4535 from Dynea, Brebie `res, France)树脂适用于在9%平衡含水率下的粘结干木。一种凝固特别快的三聚氰胺-尿素-甲醛(MUF)实验蜜月胶已被报道被Properzi et al. (2001)使用;其两部分组成如下。成分A:MUF树脂在pH值约为10,63–65%固体含量,3000–3500mP.s的粘度,无填料。成分B:38%甲酸水溶液。七块尺寸为200times;110times;15mm3的松木板(欧洲赤松)按欧洲标准EN 386(2002)在每一块梁的一面涂上成分A,另一面涂上成分B。然后施加0.6 N/mm2 的压力,并20℃的环境下放置3小时。样品按照欧洲标准EN 391(2002)和EN 392(1995)进行切割,在20°C和65%相对湿度条件下进行测定,然后进行剪切强度和木材破坏率的测试。得到的结果如表1所示,是12个测试的平均值。剩下的标本随后进行分层试验,根据EN 391,方法B:用10 – 20℃的水浸渍并在高压釜中以70 – 85kPa的压力持续30分钟紧接着在500 -600kPa压力下持续120分钟。在此之后,标本放置在75°C,8%的湿度和2米/秒的空气循环的烘箱中。待试样干燥到其初始重量的100 - 110%后进行脱层率测定。而表1中是松木梁的干剪强度、脱层率和经过单独应用蜜月黏合的快速固化MUF胶粘剂标准规定的15至18小时的干燥时间后分层试验的抗剪强度结果,这里的标本干燥时间24 h,使测试更严谨。优良的分层结果如表1所示。进行了脱层试验的木材进行了剪切强度试验根据EN 392。结果见表1。

3 Results and discussion

In Table 1, the average shear strength obtained with the honeymoon MUF adhesive is shown. While this is good, higher than the relevant European Standard requirements, and higher than what was reported for beech strip tests in a previous work (Properzi et al. 2001), it is a result that is somewhat expected for this type of adhesive. What is instead exceptional, is the excellent result of delamination and even more the average shear strength result obtained for the specimens that have already undergone the delamination test. It must be equally noted that EN 1194 (1999) gives a value of 3.2 MPa for a GL28 h class homogeneous glulam. Thus, the values obtained experimentally for the glulam beams bonded with this MUF honeymoon yield a strength value more than twice higher than what is required by the standard, even if such a statement is not representative as the standard value is at the 5 % fractile, thus much lower.

3结果与讨论

在表1中表明了蜜月MUF胶的平均剪切粘结强度。虽然这是不错的,高于欧洲相关标准要求,且高于所报道的在以前的工作中的山毛榉带试验(Properzi et al. 2001),这是这种类型的粘合剂所期望的结果。什么是优秀,是优异的分层结果甚至是已经经历了分层测试的平均剪切强度结果。必须同样指出,EN 1194(1999)给出的GL28h级均质材的值为3.2 MPa。因此,本实验的这种MUF蜜月胶合木梁的屈服强度值比要求的标准高一倍以上,即使这样的说法并不代表是标准值的5%,因此低得多。

4 Conclusion

The honeymoon method is perfectly suitable for glulam application, with high mechanical properties and great water resistance along with a short pressing time: the materiel keeps more than 75 % of its resistance after severe water exposure in a delamination test.

4结论

蜜月法非常适合于集成材应用,在短时间的压合后就有着不错的机械性能和耐水性:在分层试验

剩余内容已隐藏,支付完成后下载完整资料

资料编号:[27726],资料为PDF文档或Word文档,PDF文档可免费转换为Word

您可能感兴趣的文章

- 饮用水微生物群:一个全面的时空研究,以监测巴黎供水系统的水质外文翻译资料

- 步进电机控制和摩擦模型对复杂机械系统精确定位的影响外文翻译资料

- 具有温湿度控制的开式阴极PEM燃料电池性能的提升外文翻译资料

- 警报定时系统对驾驶员行为的影响:调查驾驶员信任的差异以及根据警报定时对警报的响应外文翻译资料

- 门禁系统的零知识认证解决方案外文翻译资料

- 车辆废气及室外环境中悬浮微粒中有机磷的含量—-个案研究外文翻译资料

- ZigBee协议对城市风力涡轮机的无线监控: 支持应用软件和传感器模块外文翻译资料

- ZigBee系统在医疗保健中提供位置信息和传感器数据传输的方案外文翻译资料

- 基于PLC的模糊控制器在污水处理系统中的应用外文翻译资料

- 光伏并联最大功率点跟踪系统独立应用程序外文翻译资料